BINDER Cooling Incubators and Constant Climate Chambers

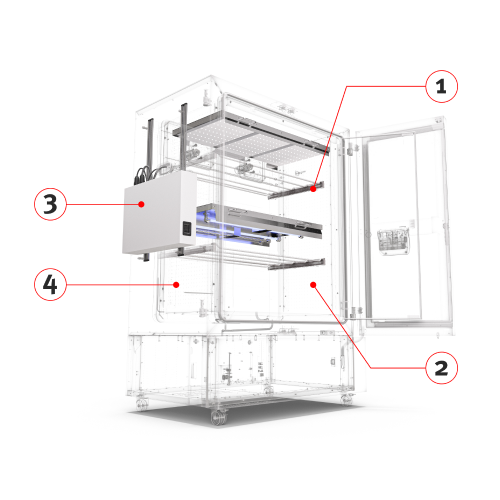

Modular design for enhanced flexibility and efficiency.

Why Choose BINDER Modular Cooling Incubators and Constant Climate Chambers?

Applicable Solutions

Related Products

Product Code 200104347

BINDER™ KBF PRO Climate Chamber

Product Code 200104346

BINDER™ KBF Constant Climate Chamber

Product Code 200104345

BINDER™ KB PRO Cooling Incubator

Product Code 200104344

BINDER™ KB Cooling Incubator

Related Videos

Designed for the laboratories of tomorrow, where innovation delivers unmatched performance, flexibility, and possibilities.

Related Documentation

Redefining Climate Chambers

Best Performance. Best Flexibility. Best Possibilities.

FAQ

The air movement in a constant climate chamber is crucial for climate homogeneity inside the unit. Only homogeneous climate conditions, both in terms of space and time, provide reliable results. Double-sided horizontal air flow allows for particularly homogeneous conditions. The air is extracted via a perforated rear wall and returned back into the usable space after reconditioning. The air is distributed evenly into the chamber via small perforations in the side walls and therefore flows evenly over the test materials from both sides.

If a plant growth chamber with humidity control is required, constant climate chambers from the KBF and KBF PRO series are available as basic units. When operated with a BINDER LED plant light module, the units regulate a temperature range from 10°C to 50°C and a relative humidity from 10% to 50% (KBF series) or 10% to 90% (KBF PRO) series. For ICH Q1B Photostability Tests, climate conditions are not required. The temperature must be maintained at a specific level to prevent any overheating effects. Humidity control is not required. The most cost-effective combination is a KB PRO paired with an ICH Light module, which fully complies with ICH guidelines.

For photostability testing according to ICH Q1B, the light source and illuminance levels are crucial. The light spectra and illuminance doses are precisely specified. Visible light (VIS similar to ISO 10977 (1993)) must reach a VIS light dosage of at least 1.2 million lux hours and near ultraviolet (320 nm to 400 nm) must reach at least 200 Wh/m². Illumination cassettes provide flexible placement, ensuring homogeneous light distribution within the interior. According to ICH guideline Q1B, a significant proportion of UV radiation must be in the ranges of 320 to 360 nm and 360 to 400 nm. BINDER photostability test chambers fully meet these requirements.